The MT52 series drill milling machining center, a small machining center with a spindle taper of 7:24 (BT30), can meet the processing requirements of parts for drilling, tapping, milling, boring, and reaming. For higher productivity, a 12000/15000/20000/24000rpm spindle can be optionally selected. The innovative MT series' high-tech innovations, whether the basic MT52A/D or the extended MT52AL/DL, meet the needs of various industries with high efficiency, high precision, and high cost-effectiveness.

MT52D series ATC system

The tool magazine can hold 14 or 21 tools. The tool-to-tool change time is 0.8 seconds, ensuring efficient tool changes and faster processing time.

|

|

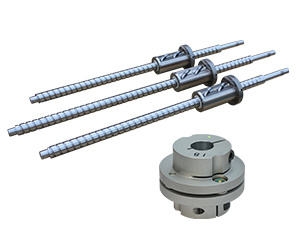

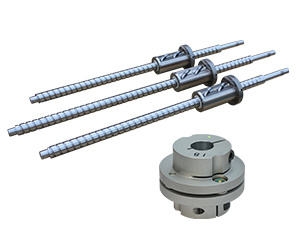

High-precision ball screw, linear guide, and coupling

The X/Y/Z axes use high-precision ball screws, high-rigidity, high-positioning accuracy ball linear guides, and SFC-type couplings. They feature good torsional rigidity, ultra-low inertia, and zero backlash, meeting the requirements of high-acceleration operation, with maximum acceleration exceeding 2.0G and a maximum rapid traverse speed of 48m/min.

|

|

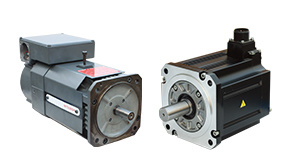

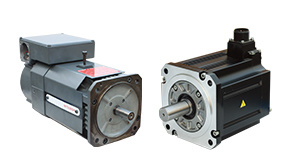

High-speed spindle motor

It uses a high-performance, new-type Mitsubishi (Japan) spindle motor, equipped with high-speed, high-precision bearings, achieving high-speed, low-vibration performance. The spindle motor speed can reach up to 12000rpm.

|

|

Cooling system

A large-capacity coolant tank and a high-power cooling motor provide sufficient cutting fluid during processing. The pull-out coolant tank design saves space and facilitates chip removal. 4-layer filtration prevents chips from entering the coolant pump.

|

|

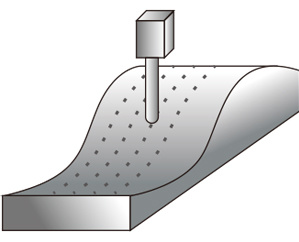

Achieving high speed, high precision, high rigidity, and high efficiency

By pre-reading multiple program segments, the program composed of continuous small movements can run at a maximum of 33.7K program segments/minute.

High-speed processing is performed. (Type B maximum 8.4k program segments/minute)

|

|

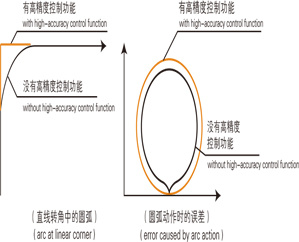

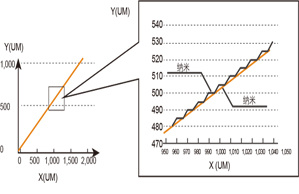

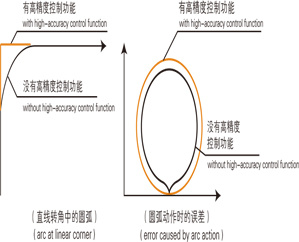

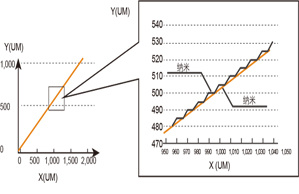

High-precision control function

Correction is performed at the corners where straight lines connect, improving arc motion and performing interpolation control according to the command trajectory.

By reducing the inward error caused by arc motion instructions, the shape trajectory control is closer to the command value.

|

|

Nano control - improving interpolation calculation accuracy

Even for instructions with a processing program unit of 1 micron, nano-unit interpolation calculation can be performed, improving program segments

|

|

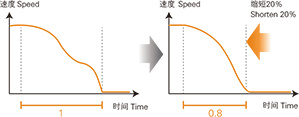

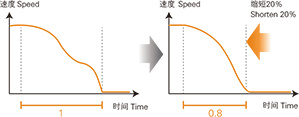

Shortening positioning time

By performing maximum torque deceleration, spindle positioning is performed in a very short time, further shortening the spindle start/stop time.

Short.

|

|

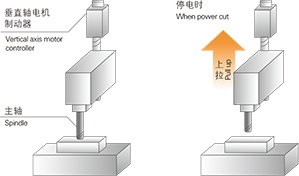

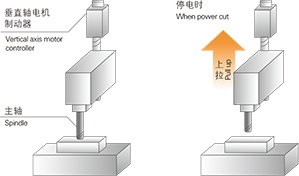

Function to prevent the spindle head from falling during a power outage

The power supply unit instantly detects a power outage and pulls up the spindle head to prevent collisions with the workpiece.

|

|

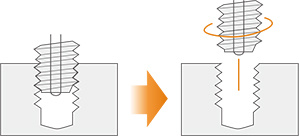

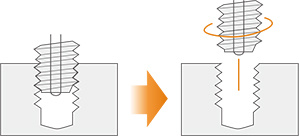

Tapping retraction function

In tapping processing, if processing is interrupted due to an emergency stop or sudden power outage, the tool can automatically retract from the workpiece after restarting.

|

|